Our aluminium

Starting as Bauxite in the earth to becoming the panels on an aircraft, discover how our aluminium is processed and where our metal goes.

Aluminium is one of the most sought-after metals in the world. It is light, strong, flexible, non-corrosive and infinitely recyclable.

In a world with evolving customer demand and a focus on sustainability and durability, aluminium is now - more than ever - the metal of the future. Australia is the world’s fifth largest producer of aluminium, known for global best practice for electricity efficiency and controlling greenhouse emissions during production.

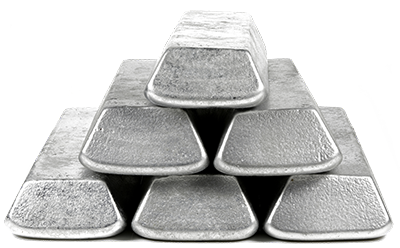

Bell Bay Aluminium produces ingot, T-bar and rolling block aluminium products.

Exported around the world

More than 90% of our produce is exported, primarily to southeast Asia, east Asia and India.

Trusted by our customers

We have relationships spanning decades with customers who trust in the quality of our aluminium.

Multiple industry applications

Our metal is custom cast for use in the transport, construction, packaging and electrical industries.

Aluminium is the third most abundant element in the Earth’s crust, but it doesn’t occur as a metal naturally.

Bell Bay Aluminium works in smelting: the final step of aluminium’s journey from bauxite to a final product.

1. Bauxite mining

The first step in producing aluminium is mining its ore – bauxite. Mined land is rehabilitated once the

bauxite is extracted from the surface.

2. Alumina refining

Alumina is a white granular material – also called aluminium oxide. Approximately two tonnes of alumina are required for every tonne of aluminium produced.

3. Aluminium smelting

Smelting is where aluminium is extracted from alumina and cast into products. Like most smelters, Bell Bay Aluminium uses the Hall-Héroult process.

The smelting process

Add Bath & Alumina

In a large rectangular cell, known as a “pot”, alumina is dissolved in a bath of molten cryolite and other materials.

Anode

Carbon blocks, called anodes, are suspended to conduct electricity through the row of pots, called the “potline”.

Electrolysis

An electric current flows through the potline, with temperatures of 950°C splitting the alumina into aluminium and oxygen.

Tapping

At regular intervals, molten aluminium is tapped from the pots and transported to the casthouse.

Casting

Aluminium is cast into its final form: at Bell Bay Aluminium, that’s ingot, T-bar and rolling block products.